Enough landmines are buried underground worldwide to circle Earth twice at the equator, but the identification and removal of these explosives is costly and time-consuming.

Vyacheslav Aranchuk, principal scientist in the National Center for Physical Acoustics, presented his research on laser multibeam vibration sensor technology at the Optica Laser Congress and Exhibition, held last week in Osaka, Japan. Aranchuk’s laser vibration sensing technology can detect landmines in the ground much faster than previous techniques.

“There are tens of millions of landmines buried around the world, and more every day as conflicts continue,” Aranchuk said. “There are military applications for this technology in ongoing conflicts and humanitarian applications after the conflicts are over.”

More than 110 million active landmines are deployed worldwide and landmines or other explosives left behind from previous wars injured or killed 4,710 people in 2022. More than 85% of landmine casualties were civilians, and half the civilian casualties were children.

Seventy countries worldwide still live with the risk of active landmines each day, including current and former war zones.

Landmines are easy to make and can cost as little as $3 apiece, but identification and disposal can cost up to $1,000 per mine to remove.

Current landmine detection mostly relies on handheld metal detectors, a technique that is dangerous and time-consuming, Aranchuk said. Metal detectors and ground-penetrating radar are not effective in finding plastic landmines.

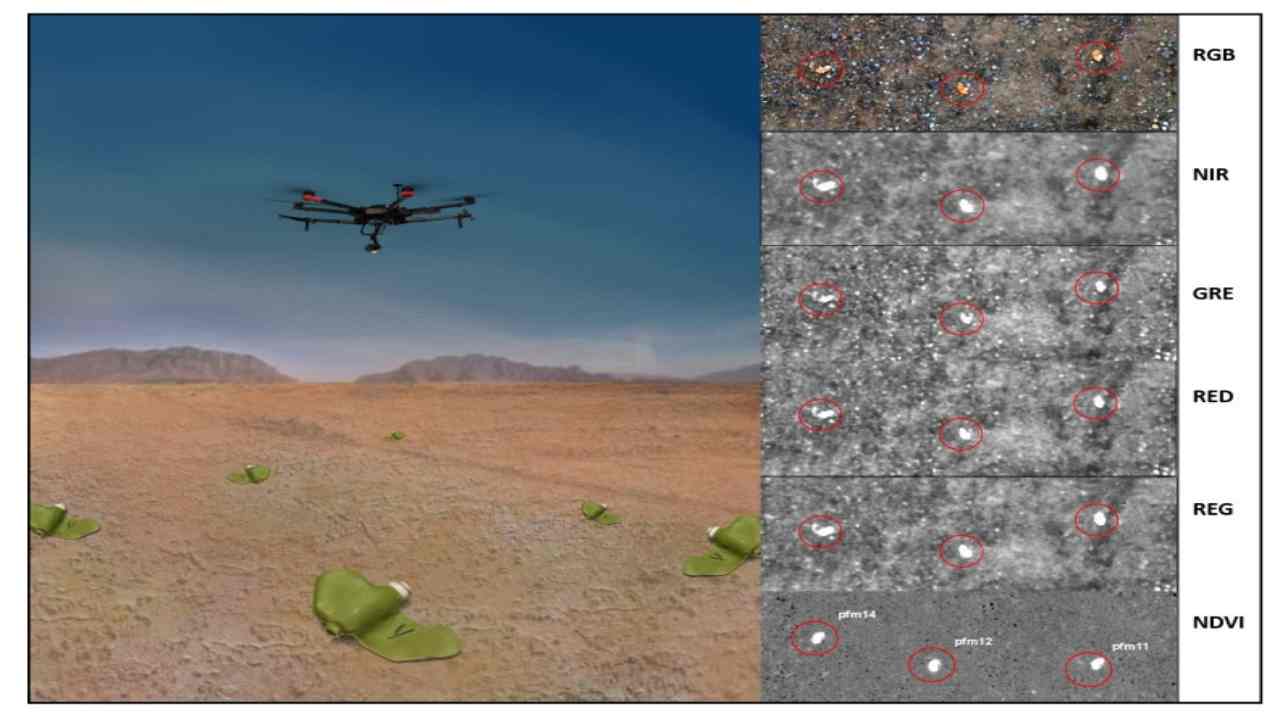

Aranchuk’s research team at Ole Miss developed a laser vibration sensor in 2019 that could find buried objects at a safe distance from a moving vehicle with 30 laser beams formed in a line.

The researchers’ latest technology can form a vibration map of the ground in less than a second. It uses a 34×23 matrix array of beams—which roughly forms a rectangle.

“Most of the modern mines are made of plastic, so they are harder targets for traditional methods of detection that look for metal,” he said. “That’s why the NCPA developed this method of detection.”

Like the 2019 technology, Aranchuk’s laser multi-beam differential interferometric sensor, or LAMBDIS, can be used from a moving vehicle, further increasing the speed at which buried landmines can be detected.

Boyang Zhang, a former postdoctoral researcher at the NCPA from Nantong, China, co-authored the report.

“Metal detectors often generate false positives by detecting any metallic object, and (ground-penetrating radar) can be hindered by certain soil conditions or materials,” Zhang said. “In contrast, laser-acoustic detection uses a combination of laser and acoustic sensing, which allows it to detect landmines from a distance with greater accuracy.

“It reduces false positives and enhances safety by keeping operators farther from the detection zone.”

To find buried objects—explosive or otherwise—the researchers create ground vibration and then cast a two-dimensional array of laser beams at the ground.

Ground vibration induces small variations to the frequency of reflected laser light, which are used to create a vibration image of the area. A buried landmine vibrates differently than the surrounding soil and appears as a red blob in the vibration image.

“The working principle is based on inference of light,” Aranchuk said. “We send beams to the ground and the interference of light scattered back from different points on the ground produces signals, which processing reveals vibration magnitude at each point of the ground surface.”

While the technology is intended to detect landmines, its applications could be numerous, the researchers said.

“Beyond landmine detection, LAMBDIS technology can be adapted for other purposes, such as assessment of bridges and other engineering structures, vibration testing and nondestructive inspection of materials in automotive and aerospace industry, and in biomedical applications,” Aranchuk said.

The next phase of Aranchuk’s research aims to investigate LAMBDIS’s performance for different buried objects and in different soil conditions.

Provided by University of Mississippi